If you’re looking for a 3D printer that can handle small parts with precision, there are a few factors to consider before making your purchase. One of the most important things to look for is a printer with a high resolution, as this will allow for greater detail and accuracy in your prints. Additionally, you may want to think about the size and type of filament that the printer can use, as well as the speed and ease of use.

Before buying a 3D printer for small parts, it’s important to think about the level of experience you have with 3D printing. Some models may be better suited to beginners, while others may require a greater degree of technical knowledge. Additionally, you should consider whether you need a printer with a large build volume or if a smaller one will suffice for your needs.

Are you tired of struggling to find a 3D printer that can handle your small projects with precision? Do you need a printer that can deliver high-quality results without breaking the bank? If so, you’re in luck! In this article, we’ll be taking a look at some of the best 3D printers for small parts on the market today. From top-of-the-line models to affordable options, we’ve got you covered. So what are you waiting for? Let’s get started!

10 Best 3D Printer For Small Parts

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

The product is ideal for DIY 3D printing with a large print size, open source, removable platform, and resume printing capabilities.

|

|

||

|

2

|

The product is ideal for creating large 3D prints with precise and smooth filament flow.

|

|

||

|

3

|

The product is ideal for creating 3D printed designs with a large build area and heated print bed.

|

|

||

|

4

|

The product is ideal for beginners and kids looking to print large-sized 3D objects with ease and precision.

|

|

||

|

5

|

The product is ideal for DIY enthusiasts looking for an affordable fully open source 3D printer with resume printing function and large print bed.

|

|

||

|

6

|

The product is ideal for kids and beginners who want a fully assembled, high precision 3D printer with Wi-Fi printing capability.

|

|

||

|

7

|

The product is ideal for DIY home and school printing with a build size of 8.66×8.66×9.84 inches.

|

|

||

|

8

|

The product is ideal for large format 3D printing with a fast-heating bed, dual Y-axis linear rails, and auto-leveling features.

|

|

||

|

9

|

The product is ideal for high precision 3D printing of materials such as nylon, carbon fiber, and PC.

|

|

||

|

10

|

The product is ideal for 3D printing with automatic bed leveling and preview model function pre-installed.

|

|

1. Lgt Pro 3d Printer With Dual Blower Upgrade.

The Upgraded Longer LK5 Pro 3D Large Printer is the perfect printing solution for enthusiasts and professionals alike. With its upgraded dual blower kit, the filament is cooled quickly after extrusion, resulting in models that are less prone to deformation or wire drawing, ensuring better printing quality.

This printer is 90% pre-assembled, making it easy to set up and use right out of the box. The build size is an impressive 300*300*400mm, and the reinforced design of diagonal rods creates a stable triangular structure that effectively reduces vibration for more stable printing.

The LK5 Pro is equipped with a silent and open-source motherboard that features TMC2208 ultra-silent drivers, which significantly reduce noise while maintaining firm properties. The open-source firmware allows for customization and experimentation with G code, giving users the freedom to try their fantastic ideas on the printer. The BL touch installation is also provided, though it's not included in the package.

The 4.3inch full-color touch screen is another standout feature of the LK5 Pro. It offers an optimized UI interface that makes operation easy and intuitive. Users can view real-time printing information on the screen, and the larger touch size of 4.3 inches is more expansive than other printers' 2.8 inches.

The LK5 Pro also comes with other useful functions, such as a lattice glass plate that makes the model easier to disassemble, and the hotbed is flatter, providing better printing results. The printer also has a recover printing function that allows users to resume printing after power loss. Additionally, the filament detection sensor system automatically suspends printing when the filament runs out to save time and filament.

2. Precise Metal 3d Printer With Large Volume.

The Anycubic Kobra Plus is a smart and precise 3D printer that offers a more intelligent printing experience. It features the new Anycubic LeviQ auto-leveling system with 25-point precise leveling up, allowing for easy control and accessibility in one touch. The printer offers filament runout detection and power off resume, equipped with filament and power detection sensors that can pause the printing process intelligently in case of running out of filament or unexpected power failure. It can resume printing from the last printing position, saving time and reducing waste.

This printer boasts a large build volume and fine printing capabilities. The printing build volume of the Anycubic Kobra Plus is 2.5 times larger than the Anycubic Mega S, offering a printing size of 300*300*350mm to satisfy all 3D printing needs. The printer is equipped with double thread Z-axis moving construction to minimize shaking and ensure high printing speed.

The Anycubic Kobra Plus offers component upgrades to achieve creative freedom, equipped with an all-metal geared extruder that heats up and melts filaments quickly, ensuring smooth filaments. The 6000RPM dual fans allow the model to cool down quickly, providing easier printing and creative freedom.

The printer offers excellent adhesion and easy removal, thanks to the carborundum glass plate that has excellent adhesion when heated. The model can be removed easily after cooling, and the plate can be used repeatedly without losing platform performance.

The Anycubic Kobra Plus offers a modular design that allows the printer to be assembled in just 10 minutes. It is easy to use and fast to get started, and it is equipped with a 4.3-inch LCD touch screen that brings sensitive response and a brighter display, offering a better user experience. All ANYCUBIC 3D printers are backed with lifetime technical support and 24-hour professional customer service.

3. Proprint Cz-300: Large Build Aluminum 3d Printer

The CZ-300 is a highly functional and compact 3D printer that is ideal for DIY enthusiasts and prototyping purposes. It offers multiple connectivity options, including USB 2.0 and the ability to print pre-loaded files onto a memory card and SDHC slot.

One of the standout features of the CZ-300 is its heated print bed, which allows for a consistent temperature range of 40 to 90 degrees Celsius. This feature is particularly useful when working with filaments that require a heated print bed.

In terms of build area, the CZ-300 provides an impressive 11.8×11.8×11.8 inches (300x300x300mm) in length, breadth and height. This larger build area allows for the printing of considerably larger models for better observation and functionality.

The printer's graphical interface is another great feature. Integrated with a 3 inch LCD display screen, it allows you to view the print status, select files, and adjust other printer parameters. The graphical interface is optimised for user-friendly usage, making it easy for even beginners to use.

The CZ-300 is also highly versatile in terms of its filament compatibility. It supports a wide range of filament types, including PLA, ABS, PETG, Carbon PLA, and metallic PLA. This enables users to experiment with various filaments to achieve different outcomes.

Finally, the CZ-300's nozzle is made of copper and has a diameter of 0.4mm. It supports a maximum temperature of 60 degrees Celsius, and is designed to deliver high-quality printing output.

4. Max Neo 3d Printer: User-Friendly Fdm Innovation.

Introducing the Creality Ender 3 Max Neo 3D printer, a powerful and efficient printing tool designed to cater to all your printing needs. With its CR Touch automatic leveling system, this printer can improve efficiency by automatically measuring and adjusting the 25-point print height on the heat bed, making leveling much easier.

Compared to other Ender 3 models, the Ender 3 Max Neo boasts a larger build volume of 300*300*320 mm, allowing for the printing of both large models and small parts, or several small models on a large build surface at the same time.

One of the standout features of this printer is its high-precision dual Z-axis, which guarantees stability and higher printing precision. Perfect coordination among dual Z-axes, timing belt, and dual motors effectively avoids printing deviation in single-axis printing and reduces the possibility of lines and bulges on your side print.

The full-metal bowden extruder is more durable and has greater extrusion force, ensuring smooth infeed and outfeed, reducing the risk of nozzle blockage. Additionally, the 32-bit silent mainboard emits noise lower than 50dB, greatly reducing noise to let you enjoy your printing.

The printer also comes equipped with a 350W high-quality built-in power supply, making it more secure and reliable, improving stability and the sense of integration. The resume printing function can accurately record data and restart the print from where it was left off, eliminating worries about sudden power failure. A filament sensor is also included to detect the sufficiency of consumables, avoiding wasting and enhancing the success rate.

Assembly of the Ender 3 Max Neo is a breeze, with 96% of the printer body pre-installed, solving the hassles and worries of parts assembly. Start your print with just three steps. The 4.3-inch color knob screen is an energy saver and will dim out in 4 minutes without operation. Optimized with icons, the UI is more vivid.

Lastly, Creality provides 12-month after-sales service for the Creality 3D printer, ensuring peace of mind and reliable support. Should you have any questions or require support about the product, their customer service team can be contacted via Amazon and will respond within 24 hours.

5. Open Source Resume 3d Printer

The Ender 3 is a high-quality 3D printer that boasts several impressive features. One of its most notable features is its ability to resume printing even after a power outage or lapse occurs. This is a crucial feature for anyone who wants to ensure that their prints are not ruined due to unforeseen circumstances.

In addition to this, the Ender 3 is also incredibly easy and quick to assemble. It comes with several pre-assembled parts, meaning that you only need about 2 hours to assemble 20 nuts well. This is a significant advantage for anyone who wants to get started with 3D printing as quickly as possible.

Another impressive feature of the Ender 3 is its advanced extruder technology. The extruder has been upgraded to greatly reduce the risk of plugging and bad extrusion. The V-shape with POM wheels make it move noiseless, smoothly and durable. This ensures that your prints come out perfectly every time, without any frustrating issues.

The Ender 3 also comes with a safety-protected power supply. It only needs 5 minutes for the hot bed to reach 110 degrees Celsius, making it incredibly efficient and convenient to use. This ensures that you can get started with your prints quickly and easily.

Finally, the Ender 3 undergoes strict testing for key components before delivery. This ensures that you receive a high-quality product that is built to last. Additionally, there is lifetime technical support available, ensuring that you can get help with any issues that may arise.

6. X-Maker: Silent, Wi-Fi 3d Printer For Beginners

The AOSEED X-MAKER 3D Printer is an excellent tool for unleashing your child's creativity with its effortless 3D printing capabilities. It comes fully assembled, requiring no complex setup or manual equipment calibration before use. The intuitive software and user-friendly interface make it easy for kids to design and print their creations, bringing their ideas to life.

This 3D printer also features wireless smart one-key printing with an intelligent optimization algorithm and WIFI printing capability. Printing is as simple as pressing a button, and it also supports SD/USB printing, allowing for printing without an internet connection. It's the perfect choice for entry-level users who want STEM education and want to start enjoying the printing experience right away.

Unlike fully open-source 3D printers, the AOSEED X-MAKER 3D Printer is enclosed, providing a range of benefits that prioritize safety for your family. Harmful fumes and emissions are isolated, and the leveling-free bed guarantees a proper distance between the nozzle and the printing surface, resulting in consistent and high-quality prints. The printer's enclosure protects your children, and they won't accidentally touch any hot or moving parts during operation.

The AOSEED X-MAKER 3D Printer comes with 15 mini-apps model library that offers an elaborate LEGO-style design apps, easier for kids and beginners to design models. There have included 15 gamified 3D design "mini-programs" to make the process even more fun and accessible. For those looking to take their creativity even further, the 2 free design software, “digital building blocks” graphic module design and “digital clay” free sculpture modeling provide a unique and tactile approach to creating your own 3D masterpieces.

This enclosed 3D Printer is designed to deliver excellent print quality with advanced printing technology. It has precision as fine as 0.1/0.05 mm and a printing rate of 160mm/s, ensuring that your prints will come out with incredible accuracy and detail. For sustainability, the 3D printer uses PLA filament, an eco-friendly material that is both durable and sustainable. This means you can enjoy high-quality prints while also doing your part to protect the planet.

The AOSEED X-MAKER 3D printer is also ultra-silent during printing, making it perfect for shared spaces and quiet environments. With a specially designed motor, the printer operates at less than 50 dB, providing a virtually silent printing session, even during long print jobs.

7. Pro 3d Printer – Build, Print & Create!

The Ceality Ender 3 Pro 3D printer is a reliable and efficient device that offers a range of features to enhance your 3D printing experience. One of the standout features of this printer is the removable build surface plate, which provides all-round protection to your 3D printer build plate and ensures consistent temperature throughout the build surface. This makes it easy to remove the printing models after cooling, allowing for a seamless printing experience.

Another great feature of the Ender 3 Pro is the safe power supply. This printer comes with a branded power supply that protects your printer from unexpected power surges, which can heat the hot bed to 110℃ in just 5 minutes. With this safety feature, you can be assured that your printer and your print job will not be compromised in the event of a power surge.

The resume print function is another convenient feature of the Ender 3 Pro. This printer can resume printing from the last recorded extruder position after suffering unexpected power outages. This means that you will not lose your print job progress in the event of a power outage.

The Ender 3 Pro comes partially assembled, making it easy to set up and allowing you to learn about the basic construction of 3D printers as you finish putting it together. This feature makes it a fun STEM educational experience in mechanical engineering and electronics.

In addition to the printer, you will also receive lifetime technical assistance and 24 hours professional customer service. This means that if you ever encounter any issues or have any questions, you can rely on the support provided to ensure that your printer is always functioning at its best.

8. Super Size 3d Printer With Auto-Leveling

The Creality CRM4 3D printer is a quasi-industrial large format printer that offers a large build volume of 450*450*470mm. This large build volume allows for the creation of bigger and more complex models with fewer or no post-processing requirements, saving a lot of time and effort for users. Additionally, the ability to batch-print multiple parts in one go is a significant advantage, increasing efficiency and productivity, making it ideal for prototyping and small production runs.

The printer features precise and reliable dual Y-axis linear rails made of bearing steel that have a load capacity of 30 kg. The Y-axis is powered by a 42-60 stepper motor that can handle a print of up to 30kg on its build plate. The Z-axis forms a rigid triangle with two support bars, ensuring better stability for the upper frame. Each Z-axis is driven by an independent motor, resulting in more precise movement of the axes.

The all-metal "Sprite" direct dual-gear extruder is a dual-gear design that allows for smooth filament feeding and discharging with a thrust of up to 80 N. This extruder is ideal for printing high-precision models and flexible filaments such as TPU. The extruder is designed for home use, ensuring smooth and reliable printing.

The Creality CRM4 3D printer is equipped with genuine 25-point auto-leveling, which allows for fully automatic leveling with CR Touch by probing 25 points for the largest auto-leveling 3D printer. The Z offset at 0.05mm accuracy quickly calibrates the distance between the nozzle and the build surface, ensuring accurate and consistent prints.

The printer's build platform is made up of a 4-layered design, with a PC coating that provides strong adhesion. The bendable spring steel sheet is easy to remove large models and will not deform after long-term use. The magnetic base and two pins allow for quick snap-on.

The Creality CRM4 3D printer gives users a variety of printing options with cloud printing capabilities through Creality Cloud software, as well as USB-A drive, USB-C cable, RJ45 LAN, and Wi-Fi connections. The printer can be easily controlled through multiple CR-M4 3D printers from one convenient location with Creality Print or Creality Cloud Web applications, enabling enhanced and streamlined production pipelines.

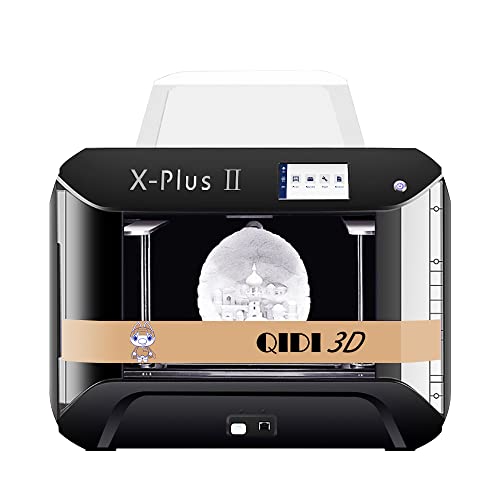

9. Qidi X-Plus2 – Industrial Grade 3d Printing Marvel

The QIDI Third Generation Extruder Assembly is a must-have for 3D printing enthusiasts. This printer features two newly upgraded extruders, with dual-gear extruders that offer more accurate printing, better heat dissipation, and less clogging. The ordinary extruder already comes installed on the printer and has a maximum printing temperature of 250℃. It works well with PLA, ABS, and TPU. The high-temperature extruder has a maximum printing temperature of 300℃ and can print Nylon, PA12-CF, and PC.

Furthermore, the QIDI X-PLUSⅡ has a double Z-axis driver that ensures more stable and precise printing quality, especially when printing large model sizes. The printer has a large print size of 10.6×7.9×7.9 inches, making it perfect for printing larger models.

The QIDI X-PLUSⅡ is also equipped with a filament detection function and resume printing capability, eliminating the need to worry about filament depletion when printing large models. The printer is equipped with a filament runout sensor that will ring to remind users when the filament is running low. In case of a power outage during the printing process, the printer will automatically save the breakpoint.

The latest slicer software version 6.5.3 has a redesigned UI interface that is smarter and more convenient to operate. The slicing algorithm has been improved, resulting in a 30 percent improvement in print quality and a 20 percent increase in speed. The QIDI software is compatible with all types of QIDI printers. If you have an old version, please download the latest version on the QIDI official website.

When you purchase the R QIDI TECHNOLOGY X-PLUSⅡ, you receive a free one-year warranty and lifetime technical assistance. The professional after-sale service team will help customers solve any problems within 12 hours, ensuring a stress-free experience for all users.

10. Ender 3 V2 Auto-Level 3d Printer

The Creality Ender 3 V2 Neo 3D Printer is the perfect choice for anyone who wants precision, reliability, and ease of use when it comes to 3D printing. Equipped with the CR-Touch auto bed leveling system, this printer is able to gather bed deviation data by touching multiple points on the bed and compensating for them accordingly, resulting in hassle-free bed leveling and enhanced accuracy.

One of the key features of this printer is the metal Bowden extruder, which is more durable and has more extrusion force than plastic extruders found in other models such as the Ender 3, Ender 3 Pro, and Ender 3 V2. This allows for a smoother and more efficient printing process.

The Ender 3 V2 Neo also features a brand new 4.3 inch UI user interface, which has been upgraded with a model preview function that makes it easier to observe the printing shape and progress for customers. It also supports nine languages for different customer demands, making it accessible to a wider range of users.

In addition, the printer comes equipped with a silent motherboard 32-bit 4.2.2 version, which is different from the mainboard found in the Ender 3. The self-developed silent motherboard has stronger anti-interference, faster and more stable motion performance, silent printing, and low decibel operation, creating a quiet environment for users. The extruder has also been upgraded to a full-metal extruder, which has greater extrusion force and is more durable, reducing the risk of nozzle blockage.

The PC spring steel magnetic build plate found in the Ender 3 V2 Neo is also a unique feature. The innovative printing platform is a combination of a PC coating, a spring steel sheet, and a magnetic sticker, which sticks to the surface immediately when released. The PC coating brings good adhesion for filament, and the finished models can be easily removed by bending the print sheet.

Assembly is made easy with the 95% pre-installed printer, which saves users time and avoids potential problems caused by installation errors. The printer also features a recovery printing function and supports recovery printing when there is a power failure, reducing the risk of print failure.

The Creality Ender 3 V2 Neo 3D Printer also comes with an upgrade module spring made of alloy steel material, which is more elastic and strengthened. The 4.3 inch color knob screen allows for easy previewing, viewing, and checking of the effect after molding.

As the ONLY Creality 3D Official store, customers can be assured of 24/7 customer service and 1-year limited and lifetime technical assistance from over 20 engineers for after-sales service. Contact the seller directly for quick and professional assistance. Overall, the Creality Ender 3 V2 Neo 3D Printer is a reliable, efficient, and easy-to-use option for anyone looking to enter the world of 3D printing.

Best 3D Printer For Small Parts FAQs

Are there any specific materials that are better suited for printing small parts?

Yes, there are specific materials that are better suited for printing small parts. One of the most common materials used for printing small parts is resin. Resin is a liquid material that hardens when exposed to ultraviolet (UV) light. It has a high level of detail and accuracy, making it ideal for printing small parts with intricate designs. Another material that is suitable for printing small parts is nylon. Nylon is a strong and durable material that can withstand high temperatures and pressure. It has good mechanical properties and can be used to print small parts that require high strength and stiffness. Other materials that are commonly used for printing small parts include polycarbonate, ABS, and PETG. When choosing a material for printing small parts, it is important to consider the specific requirements of the part, such as strength, flexibility, and temperature resistance, as well as the printing technology being used.

Can a 3D printer be used for creating small mechanical parts and components for machinery?

Yes, a 3D printer can be used for creating small mechanical parts and components for machinery. 3D printing technology has advanced significantly over the years and now offers high precision and accuracy, making it suitable for creating complex mechanical parts and components. Using 3D printing technology for creating mechanical parts and components can also save time and costs associated with traditional manufacturing methods. It allows for rapid prototyping and design iterations, enabling engineers and designers to test and refine their designs quickly. Additionally, 3D printing can produce parts with intricate geometries that may not be possible with traditional manufacturing methods. However, it is important to note that the choice of material for 3D printing is crucial as the strength and durability of the final product depend on the material used.

Can a low-cost 3D printer produce high-quality small parts?

Yes, a low-cost 3D printer can produce high-quality small parts if the printer is properly calibrated and maintained. The key to achieving high-quality prints is to understand the limitations of the 3D printer and adjust the settings accordingly.

One of the main factors that affect the quality of the print is the layer height. The smaller the layer height, the smoother the surface finish of the print will be. However, printing at a smaller layer height will increase the print time. Therefore, finding the right balance between print quality and print time is important.

Another factor that affects the quality of the print is the filament used. Using high-quality filament with consistent diameter and good adhesion properties will result in better prints.

In conclusion, a low-cost 3D printer can produce high-quality small parts if the user understands how to optimize the settings and uses good quality filament. It may require some trial and error, but with practice and patience, high-quality prints can be achieved.

How important is the level of detail that can be achieved with a 3D printer when producing small parts?

The level of detail that can be achieved with a 3D printer is crucial when producing small parts. Small parts require a high level of precision and accuracy to function correctly, and a 3D printer with a high level of detail can ensure that the parts are produced with the required level of precision. The level of detail that can be achieved with a 3D printer is measured in microns, and the smaller the micron level, the higher the level of detail that can be achieved. For small parts, a 3D printer with a micron level of 50 or less is ideal, as it can produce small details with high precision. The level of detail also affects the quality of the finished product, as parts produced with a printer that has a low level of detail may require additional finishing work to achieve the required level of precision. Overall, the level of detail that can be achieved with a 3D printer is essential when producing small parts and can have a significant impact on the quality and functionality of the finished product.

How important is the software that comes with a 3D printer for producing small parts?

The software that comes with a 3D printer is essential for producing small parts. This is because the software plays a crucial role in the entire 3D printing process. It is used to create a 3D model of the part you want to print, and then it converts the model into a format that the printer can understand. The software also controls the printer's settings, such as the temperature, speed, and layer thickness, which are all critical factors that influence the final quality of the part.

Furthermore, the software also provides features for customizing and adjusting the part's design, such as scaling, rotating, and adding support structures. These features are crucial for producing small parts that may have intricate details, as they help ensure that the final product is accurate and precise.

Therefore, having reliable software that is user-friendly and has all the necessary features is essential for producing small parts with a 3D printer. It can save time, improve accuracy, and reduce the risk of errors and failed prints.

What are the main advantages of using a 3D printer for small part production, as opposed to traditional manufacturing techniques?

Using a 3D printer for small part production has several advantages over traditional manufacturing techniques. Firstly, 3D printing allows for greater design freedom, as complex geometries can be easily created without the need for expensive tooling or molds. This makes it ideal for creating prototypes or small production runs of customized parts.

Secondly, 3D printing offers faster turnaround times than traditional manufacturing methods. With a 3D printer, parts can be produced in hours or days, compared to weeks or months for traditional manufacturing. This is particularly useful for small businesses or startups that need to rapidly iterate designs and bring products to market.

Thirdly, 3D printing can be more cost-effective than traditional manufacturing techniques for small production runs. This is because there are no minimum order quantities or setup costs associated with 3D printing, making it ideal for small businesses or individuals who need to produce small quantities of parts.

Finally, 3D printing is a more sustainable option as it produces less waste than traditional manufacturing. Traditional manufacturing techniques often produce excess material that cannot be reused, whereas 3D printing only uses the exact amount of material required to produce the part.

Overall, the advantages of using a 3D printer for small part production make it a compelling choice for businesses and individuals looking for faster, more cost-effective, and sustainable manufacturing options.

What are the most important features to look for when selecting a 3D printer for small parts?

When selecting a 3D printer for small parts, there are several important features to consider. Firstly, the printer's resolution and accuracy are crucial. Look for a printer that has a high resolution and accuracy so that your small parts come out perfectly. Secondly, the printer's build volume is important because it determines the maximum size of the parts you can print. Make sure the printer you choose has a large enough build volume to accommodate the size of your parts. Thirdly, the printer's material compatibility is key. Different printers are compatible with different materials, and you need to ensure that the printer you choose can print with the material you require. Fourthly, consider the printer's speed and print quality. You want a printer that can produce small parts quickly without sacrificing quality. Finally, the printer's price should also be a factor in your decision-making process. Look for a printer that fits your budget but also meets all of your requirements.

What is the average print speed for 3D printers that are used for small part production?

The average print speed for 3D printers used for small part production can vary depending on various factors such as the complexity of the part, the resolution of the printer, and the type of material used for printing. However, most 3D printers used for small part production have a print speed ranging from 30mm/s to 150mm/s. It is worth noting that faster print speed may compromise the quality of the final product, as it may result in poor surface finish and accuracy. On the other hand, slower print speed may produce better quality parts but may take longer to complete the printing process. It is essential to find the right balance between print speed and quality to achieve the desired outcome. It is advisable to consult the printer's manufacturer for more specific information on the recommended print speed for a particular printer and material combination.

What is the maximum size of small parts that can be printed on a 3D printer?

The maximum size of small parts that can be printed on a 3D printer depends on the specific 3D printer's capabilities. However, most 3D printers have a minimum layer height of around 0.1mm, which means that the smallest detail that can be printed is usually around 0.1mm in size. The size of the part also depends on the printing technology and the material used. For example, if you are using a Fused Deposition Modeling (FDM) printer, the smallest feature size will be limited to the size of the extruder nozzle. On the other hand, if you are using a Stereolithography (SLA) printer, the smallest feature size will be determined by the wavelength of the laser used to cure the resin. In general, most 3D printers are capable of printing small parts with high precision and accuracy, but it's always important to check the specifications of your printer to ensure that it can meet your specific requirements.

Which 3D printers are best suited for printing small parts with high precision?

When it comes to printing small parts with high precision, there are several 3D printers that stand out from the rest.

One of the best options is the Ultimaker S5, which is known for its high print quality and precision. It has a build volume of 330 x 240 x 300 mm and can print with a layer height as low as 20 microns. Additionally, it has a range of advanced features, such as automatic bed leveling and a filament flow sensor, that make it easier to get consistent and accurate prints.

Another great option is the Formlabs Form 3, which uses a resin-based printing process to achieve extremely high levels of detail and accuracy. It has a build volume of 145 x 145 x 185 mm and can print with a layer thickness as low as 25 microns. The Form 3 also has a range of features that help ensure accurate prints, such as a self-leveling build platform and a resin management system.

Finally, the Prusa i3 MK3S is another excellent option for printing small parts with high precision. It has a build volume of 250 x 210 x 210 mm and can print with a layer height as low as 20 microns. The Prusa i3 MK3S is also known for its reliability and ease of use, with features like automatic bed leveling and a removable magnetic build plate.

Overall, any of these three 3D printers would be a great choice for printing small parts with high precision.