If you’re looking for a versatile and efficient hotend, a 2 in 1 out hotend is definitely worth considering. This type of hotend allows you to print with two different filaments, giving you the ability to create multi-colored or multi-material prints with ease.

Before buying a 2 in 1 out hotend, there are some key factors to consider. Firstly, it’s important to check that the hotend is compatible with your 3D printer and that it fits securely. You should also look for a hotend that has good heat distribution to ensure consistent printing. Consider the size of the nozzle and the filament diameter it can handle as well.

If you’re unsure if a 2 in 1 out hotend is right for you, ask yourself some questions. Do you want to be able to print multi-color objects? Do you want to experiment with different materials? Are you looking to save time by printing parts with multiple materials at once? If the answer is yes to any of these questions, then a 2 in 1 out hotend could be a great investment for you.

Overall, a 2 in 1 out hotend is a great option for those looking for versatility and efficiency in their 3D printing. By considering the compatibility, heat distribution, nozzle size and filament diameter, you can ensure that you choose the best 2 in 1 out hotend for your needs.

10 Best 2 In 1 Out Hotend

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

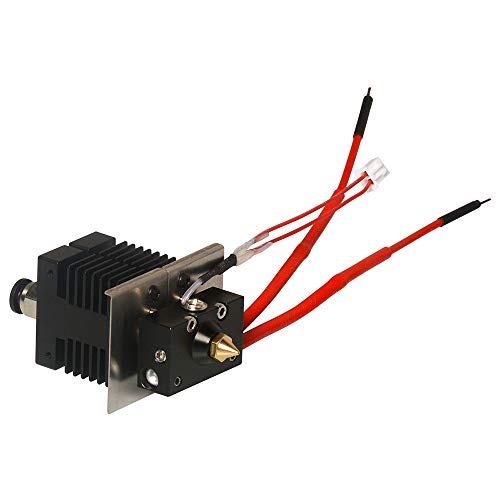

This product is ideal for 3D printing with multiple colors using a hotend and bowden extruder setup.

|

|

||

|

2

|

This product is ideal for 3D printing multiple colors with dual extruders and a silicone sock for precise temperature control.

|

|

||

|

3

|

The product is ideal for multi-color 3D printing with dual extruders and a hotend kit.

|

|

||

|

4

|

The product is ideal for reducing clogging or jamming in 3D printers when using 1.75mm filament and a 0.4mm nozzle extruder.

|

|

||

|

5

|

This product is ideal for 3D printing with dual colors or materials using compatible extruders and a Bowden setup.

|

|

||

|

6

|

This product is ideal for enhancing 3D printer performance with a dual color metal hotend and a compatible brass nozzle.

|

|

||

|

7

|

It is ideal for 3D printing with multiple colored filaments using a Titan or Bulldog extruder.

|

|

||

|

8

|

This product is ideal for repairing or upgrading a 3D printer with a multi-color printing capability.

|

|

||

|

9

|

This product is ideal for multi-color printing with the ability to extrude two filaments simultaneously, compatible with specific extruders.

|

|

||

|

10

|

This product is ideal for 3D printing with two colors or materials simultaneously using various extruders and a Bowden setup.

|

|

1. Multi-Color Hotend Kit For 3d Printing.

The Aluminum alloy 6063 material used in this product is of high quality and is known for its durability. It has undergone a refined sandblasting oxidation treatment that improves the surface texture and gives it an attractive appearance.

Compared to similar products, the heat dissipation efficiency of this product has been increased by 40%. This improvement effectively reduces and avoids the occurrence of throat plug, ensuring an uninterrupted printing experience.

The Nozzle is remarkably lightweight, weighing at least 20-30% less than other products of the same type. The reduction in weight improves printing accuracy and quality, resulting in a smooth and seamless printing experience.

The product has been designed to make sure that the total height of the product does not change by more than 0.5-1.0mm. This feature is highly beneficial for mass production and ensures consistency in the size of the printed objects.

This hotend is compatible with both HT-NTC100K and NTC100K thermistors, making it versatile and compatible with a wide range of machines. It is a high-quality product that is built to last and improve your printing experience.

2. Multi-Color Hotend Kit With Dual Extruder

This product boasts of its high quality Aluminum alloy 6063 material and refined sandblasting oxidation treatment which enhances its surface texture. It has an increased heat dissipation efficiency of up to 40% compared to other similar products in the market. This feature effectively reduces and prevents the occurrence of throat plug, making it a reliable and efficient choice for 3D printing enthusiasts.

The nozzle is designed to be at least 20-30% lighter than its counterparts, which results in improved printing accuracy and quality. Its new design ensures that the total height of the product remains consistent, with a size change of less than 0.5-1.0mm. This feature makes it a suitable option for mass production.

Moreover, this hotend is compatible with both HT-NTC100K and NTC100K thermistors, providing versatility for various 3D printing projects. Overall, this product is a durable, efficient, and reliable option for 3D printing enthusiasts and professionals alike.

3. Bz Chimera Dual Extruder: High-Tech 3d Printing

Introducing the Chimera 2 In 2 Out – Dual Extrusion System, the perfect solution for adding conventional dual extrusion to your 3D printing machine. This innovative system is designed to deliver a simple, air-cooled package that is both neat and effective.

With Chimera, you can easily adjust the nozzles' height individually, making the setup experience a breeze. Each nozzle is also independently temperature controllable, allowing for ultimate material versatility. This means that you can print with different materials and colors without any hassle, all with the same hotend.

Chimera is the result of combining the best features of its cousins, the V6 and Kraken, into a single, reliable, and highly capable hotend. This ensures that you get consistent and high-quality prints every time.

If you have any questions regarding the Chimera system, their customer service team is always ready to help. You can reach them via email, and they guarantee to respond to your inquiries within 24 hours.

Upgrade your 3D printing experience with Chimera, and enjoy the convenience and versatility that it offers.

4. Geeetech A10m/a20m 2-In-1 Extruder Kit

This exceptional 2-in-1 out hot end kit is an ideal choice for A10M and A20M 3D printers. Its innovative design significantly minimizes the risk of clogging or jamming, which ultimately saves filament for you. It is equipped with a 0.4mm standard nozzle that delivers an incredibly smooth surface finish, ensuring that your prints are of the highest quality.

This hot end kit's standout feature is its ability to uniformly mix two different color filaments to create stunning prints. Whether you're a professional or a hobbyist, this feature is sure to enhance your printing experience. Mix-color printing enriches your daily life and provides a creative outlet for you to explore.

The heater cartridge has a voltage of 24V and a power of 40W, while its diameter and length are 6mm and 30mm, respectively. The thermistor, PT3-25E2-S2, ensures accurate temperature readings, enabling you to achieve the best results possible.

Investing in this 2-in-1 out hot end kit will undoubtedly take your 3D printing game to the next level. Its easy-to-use design and compatibility with A10M and A20M 3D printers make it a must-have accessory for any enthusiast. Get ready to produce high-quality, eye-catching prints that are sure to impress!

5. Dual-Tone Extruder: 2 In 1 Bowden Compatible

Introducing the 2 in 1 out Hotend, the perfect solution for all your printing needs. This hotend boasts a filament size of 1.75mm and a nozzle size of 0.4mm, ensuring precise and high-quality prints every time. The heater wire is 12V/40W and the Thermistor is 100K NTC 3950, providing efficient heating and temperature control.

Please note that a 25x25x10mm size fan is required for optimal performance and should be purchased separately. The fan can easily be mounted onto the heatsink using an M3x14mm self-tapping screw. The back holes are specifically designed for easy installation of the hotend onto your printer.

This 2 in 1 out hotend is compatible with Bulldog, Titan, and other types of Bowden extruders, with the Bulldog extruder being recommended for optimal results. The square heat dissipation design is not only novel and unique, but it can also be equipped with V6 and Volcano Heating blocks.

Compared to a single or double head extruder, the double color extruder has significant advantages and can meet the requirements of both single and double head printing. Filament switching is fast and stable, with no obvious printing defects and precise positioning. The dual nozzle extrusion is also great at eliminating leakage.

Firmware modification is simple and easy to use, making the 2 in 1 out hotend an excellent choice for both beginners and professionals alike. With its exceptional performance and versatility, the 2 in 1 out hotend is a must-have for anyone serious about 3D printing.

6. Metal Dual-Color Hotend For 3d Printing

Introducing the 2-in-1 Extruder Kit, perfectly compatible with Ender-3, Ender-3 Pro, CR-10S Pro, and CR-10 Max 3D printers. This innovative kit is designed to take your printing to the next level by adding a splash of color to your creations.

The 2-in-1 Extruder Kit is incredibly versatile – it allows for both single-color and dual-color filament printing, giving you the freedom to unleash your creativity and add unique, eye-catching designs to your prints. However, it's important to note that this kit is not intended for mixing colors.

With the 2-in-1 Extruder Kit, you can easily switch between colors, allowing you to create intricate patterns and designs with ease. This kit is perfect for those who want to add a touch of personality to their prints, whether it's for personal or professional use.

The kit is easy to install and comes with all the necessary hardware and instructions to get started. You'll be up and running in no time, ready to create stunning, vibrant prints that are sure to impress.

7. Colorpro 3d Printer Hotend – Multi-Extruder Marvel!

The extruder kit being reviewed is a versatile tool for 3D printing enthusiasts. It boasts a filament size of 1.75mm and nozzle size of 0.4mm, while its heater wire is rated at 12V/40W. Its thermistor is 100K NTC 3950, and its main heat sink block measures 60*27*27mm.

This extruder kit is perfect for single color filament printing, dual colors filament printing or 3 colors filament switching printing. However, it is not recommended for mixing colors. It has a Bowden feeding system and is compatible with Bulldog, Titan or other types of Bowden extruder. The Bulldog extruder is the recommended choice.

One of the standout features of this extruder kit is its fast and stable color switching, which does not result in significant print quality defects. Additionally, firmware modification is simple and user-friendly.

8. Colorblend 3d Printer Hotend – Dual Filament Compatible

Introducing the high-quality 3D printing accessory – an Aluminum Alloy Extruder Kit! This kit is expertly crafted from premium grade aluminum alloy material, ensuring durability and long-lasting performance. The extruder kit is compatible with a 1.75mm filament, making it suitable for a wide range of 3D printing applications.

With a nozzle size of 0.4mm, this extruder kit is perfect for creating intricate and detailed 3D prints with ease. It comes in two sleek color options, red and black, to suit your personal style and preference. Whether you're a professional 3D printer or a hobbyist, this extruder kit is a must-have accessory for your 3D printing setup.

This Aluminum Alloy Extruder Kit is designed to provide high-quality and efficient 3D printing performance. It is easy to install, and its user-friendly design ensures seamless operation. With its durable construction, this extruder kit is built to last and withstand the rigors of frequent use.

So, if you're looking for a reliable and high-quality extruder kit for your 3D printer, look no further than this Aluminum Alloy Extruder Kit. It's the perfect accessory for taking your 3D printing game to the next level!

9. Multi-Color 2-In-1 Hotend Upgrade

Introducing the Cyclops Hotend, a powerful and versatile tool for your printing needs. With a filament size of 1.75mm and nozzle size of 0.4mm, this hotend is built to handle a wide range of printing tasks. Its heater wire comes with a powerful 12V/40W motor, and the thermistor is a 100K NTC 3950 model, ensuring top-notch printing performance.

One of the most exciting features of the Cyclops Hotend is its remote feeding capability. This hotend is compatible with a range of extruders, including Bulldog, Titan, and various types of Bowden extruders. However, the manufacturers recommend using the Bulldog extruder for optimal performance.

Another standout feature of the Cyclops Hotend is its ability to use m3 size PT100 or other thermocoupler high-temperature sensors for high-temperature printing. With this capability, you can print high-temperature materials with ease and confidence.

The heatbreak fixing hole is another well-designed feature of the Cyclops Hotend. It is located on the side of the heatsink, which means that you can remove the heatbreaks without having to move the entire hotend out of the printer. This saves time and effort and makes maintenance a breeze.

10. Hotend Kit: Dual Color Extruder Upgrade (1.75mm)

This hotend package includes a heater and thermistor and is designed to work with 1.75mm filaments. The nozzle size is 0.4mm and the heater wire is 12V/40W. The thermistor is a 100K NTC 3950 and the connector may be black dupont or white XH2.54. Please note that a 25x25x10mm size fan is required but not included, and it can be mounted on the heatsink using an M3x14mm self-tapping screw.

To install the hotend onto a printer, the back holes are utilized. Filament color switching backing waiting distance is measured at 34mm with Cura and printing PLA, and must be the same as the manual distance. The erase tower volume must be not less than 55mm³. This hotend has a smaller size, bigger heatsink area, shorter backing waiting distance, higher printing quality, and shorter printing time.

Installation of this hotend is simple, with fan installation holes that are reserved and fixed firmly. The side-installing heatbreak's fixing screw allows for easy exchange of the hotend. This hotend is a 2 in 1 out design, allowing for fast and stable filament switching. It eliminates the leakage of the dual nozzle extrusion and offers precise positioning. Firmware modification is simple, making it easy to use.

Best 2 In 1 Out Hotend FAQs

Can a 2 in 1 out hotend be used with dual extruder printers?

No, a 2 in 1 out hotend cannot be used with dual extruder printers. A 2 in 1 out hotend is designed to combine two filaments into a single nozzle to create multi-color or multi-material prints. On the other hand, dual extruder printers have two separate nozzles, allowing for simultaneous printing with two different filaments or colors.

Attempting to use a 2 in 1 out hotend with a dual extruder printer would result in several issues, including clogging, uneven filament flow, and inaccurate color mixing. It is important to ensure that the hotend is compatible with the printer before attempting to use it.

If you are looking to upgrade your dual extruder printer to include multi-color or multi-material printing, it would be more appropriate to consider a dual extruder with a 2 in 2 out hotend or a dual extruder with two separate hotends.

How does a 2 in 1 out hotend affect the quality of the printed object?

A 2 in 1 out hotend is a type of extruder that allows for two filaments to be fed into the same nozzle. This can be used to create multicolor prints or prints with a different material for support structures. The quality of the printed object can be affected by several factors when using a 2 in 1 out hotend.

One factor is the calibration of the hotend. If the two filaments are not properly calibrated, the extrusion may be uneven, resulting in a lower quality print. Additionally, the transition between filaments can also impact the quality of the print. If the transition is not smooth, it may result in a visible seam or an inconsistent color.

Another factor to consider is the type of filament being used. Some filaments may not work well with a 2 in 1 out hotend, or may require different settings for optimal printing. It is important to experiment with different filaments and settings to find the best combination for your specific 3D printer.

Overall, a 2 in 1 out hotend can be a useful tool for creating unique and complex prints, but it requires proper calibration and experimentation to achieve the best results.

How easy is it to install and use a 2 in 1 out hotend?

Installing and using a 2 in 1 out hotend can be a bit challenging for beginners, but with some basic knowledge and experience, it can be relatively easy. The installation process usually involves disassembling the existing hotend and replacing it with the new 2 in 1 out hotend. It's important to follow the instructions carefully and ensure that all the components are properly installed and secured.

Once installed, using a 2 in 1 out hotend requires some adjustments to the slicing software to enable dual extrusion. This can involve setting up different toolheads, nozzle sizes, and temperature profiles for each extruder. However, most modern slicing software has built-in support for dual extrusion, making this process easier and more user-friendly.

Overall, the ease of installing and using a 2 in 1 out hotend depends on your level of experience with 3D printing and familiarity with the particular brand and model of hotend. With some patience, practice, and troubleshooting, it's possible to achieve great results with a 2 in 1 out hotend.

What are some common issues that users face when using a 2 in 1 out hotend?

A 2 in 1 out hotend is a type of extruder that allows users to print with two different filaments or colors at the same time. While this feature can be useful for creating multi-colored or multi-material prints, there are some common issues that users may face when using a 2 in 1 out hotend.

One common issue is the difficulty in properly calibrating the hotend. Since there are two different filaments running through the hotend, it can be challenging to ensure that both extruders are properly calibrated and that the nozzle height is correct for both filaments. This can result in uneven extrusion, filament jams, and poor print quality.

Another issue is the potential for filament cross-contamination. If one filament is left in the hotend for too long, it can melt and mix with the other filament, resulting in unexpected color changes or clogs in the hotend.

Finally, the added complexity of a 2 in 1 out hotend can make it more difficult to troubleshoot issues when they arise. If one of the extruders is not working properly, it can be challenging to determine the root cause of the issue and make the necessary adjustments.

To avoid these issues, it's important to carefully calibrate the hotend, regularly clean the nozzle and hotend, and use high-quality filaments that are compatible with the hotend.

What are some of the best 2 in 1 out hotends available on the market?

There are several great 2 in 1 out hotends available on the market today. One of the most popular options is the E3D Chimera+. This hotend offers a compact design with high-quality construction and reliable performance. It features a dual-nozzle design that allows for easy switching between two different materials or colors. Another great option is the Mosquito Magnum 2. This hotend is designed with precision and performance in mind, and it features a dual-fan cooling system that ensures consistent and reliable printing. The Slice Engineering Mosquito Hotend is also a great choice for those looking for a high-quality 2 in 1 out hotend. It offers a compact design with excellent thermal performance and precise filament control. Ultimately, the best 2 in 1 out hotend for your needs will depend on your specific requirements and preferences, so it's important to do your research and choose a hotend that meets your unique needs.

What are the advantages of using a 2 in 1 out hotend compared to a regular hotend?

A 2 in 1 out hotend offers several advantages over a regular hotend. Firstly, it allows for multi-color or multi-material printing without the need to manually switch filaments. This saves time and reduces the risk of print errors caused by manual filament switching. Secondly, it enables the printing of complex geometries and intricate designs with multiple colors or materials, allowing for greater design flexibility. Thirdly, it can increase print speed as two filaments can be printing simultaneously. Finally, a 2 in 1 out hotend typically has a smaller form factor than two separate hotends, saving space on the printer and making it easier to install and use. Overall, a 2 in 1 out hotend is a versatile and efficient tool for creating high-quality 3D prints with multiple colors or materials.

What factors should be considered when choosing the best 2 in 1 out hotend for a specific 3D printing project?

Choosing the best 2 in 1 out hotend for a specific 3D printing project requires careful consideration of several factors. Firstly, the type of materials to be used in the project should be considered, as different hotends are suitable for different materials. For instance, some hotends are better suited for printing with flexible filaments while others work best with high-temperature materials like nylon and polycarbonate.

The size of the hotend is also important, as it determines the maximum size of the printed object. Additionally, the type of printer, its compatibility with the hotend, and its overall printing capabilities should be considered.

The nozzle size of the hotend is another important factor, as it determines the level of detail and precision that can be achieved in the printed object. The temperature range of the hotend is also crucial, as it determines the maximum temperature that can be used for printing.

Lastly, the cost and availability of the hotend should also be considered, as some hotends may be more expensive or harder to find than others. By taking these factors into account, one can choose the best 2 in 1 out hotend for their specific 3D printing project.

What is a 2 in 1 out hotend and how does it work?

A 2 in 1 out hotend is a type of extruder used in 3D printing that allows for two different filaments to be used in a single print. This type of hotend has two inputs and one output, which means that two different filaments can be loaded into the hotend at the same time and the printer can switch between them as needed.

The way a 2 in 1 out hotend works is by using a mixing chamber to blend the two filaments together before they are extruded. The mixing chamber is a small area inside the hotend where the two filaments are combined and then pushed out through a single nozzle.

When the printer needs to switch between the two filaments, it simply stops extruding one and starts extruding the other. This can be done manually by the user or automatically by the printer's software, depending on the model.

2 in 1 hotends are popular among makers who want to create multi-colored prints or prints with different materials. However, they do require some additional setup and calibration to ensure that the two filaments are properly blended and extruded.

What is the maximum temperature that a 2 in 1 out hotend can reach?

The maximum temperature that a 2 in 1 out hotend can reach depends on the specific model and manufacturer. However, most dual extruder hotends are capable of reaching temperatures up to 300-320°C for printing with materials such as ABS, Nylon, and Polycarbonate. It is important to note that printing at higher temperatures may require additional modifications to the printer, such as upgrading the cooling system or using a higher wattage power supply. Additionally, printing with certain materials at high temperatures can release harmful fumes, so it is important to use proper ventilation and safety measures. It is always recommended to check the manufacturer's specifications and guidelines for the hotend before attempting to print at high temperatures.

What materials can be used with a 2 in 1 out hotend?

A 2 in 1 out hotend allows for the use of two different filaments in a single print. This opens up a range of possibilities for creating multi-colored or multi-material prints.

In terms of materials that can be used with a 2 in 1 out hotend, it depends on the specific hotend and its capabilities. However, in general, most 2 in 1 out hotends are capable of printing with PLA, ABS, PETG, Nylon, and TPU. Some hotends may also be able to print with more exotic materials like PC, PVA, or even metal-infused filaments like copper or bronze.

It's important to note that when using a 2 in 1 out hotend, the two filaments being used should have similar melting temperatures and properties. This will ensure that they melt and extrude evenly, resulting in a high-quality print.